Understanding China CNC Lathe Parts: A Comprehensive Guide for Metal Fabricators

In the world of manufacturing, precision is paramount. Among the various tools that enhance accuracy in production, China CNC lathe parts stand out as indispensable components. In this article, we will delve into the intricacies of CNC lathe parts produced in China, their applications, benefits, and why they are essential for metal fabricators.

What are CNC Lathe Parts?

CNC, which stands for Computer Numerical Control, refers to the automated control of machine tools by means of a computer. A lathe is a machine tool that rotates a workpiece about an axis to perform various operations such as cutting, sanding, drilling, or deformation. The synergy of these technologies forms the backbone of modern machining processes.

CNC lathe parts are the components that contribute to the functionality and precision of a CNC lathe machine. These parts include various items such as spindles, tailstocks, tool holders, and more. Each part plays a critical role in the overall operation and efficiency of the machining process.

The Importance of China CNC Lathe Parts in Metal Fabrication

The manufacturing landscape has evolved significantly, and China has emerged as a global leader in the production of CNC lathe parts. This prominence comes from several factors:

- Cost-Effectiveness: The ability to source high-quality parts at competitive prices is crucial in maintaining profitability.

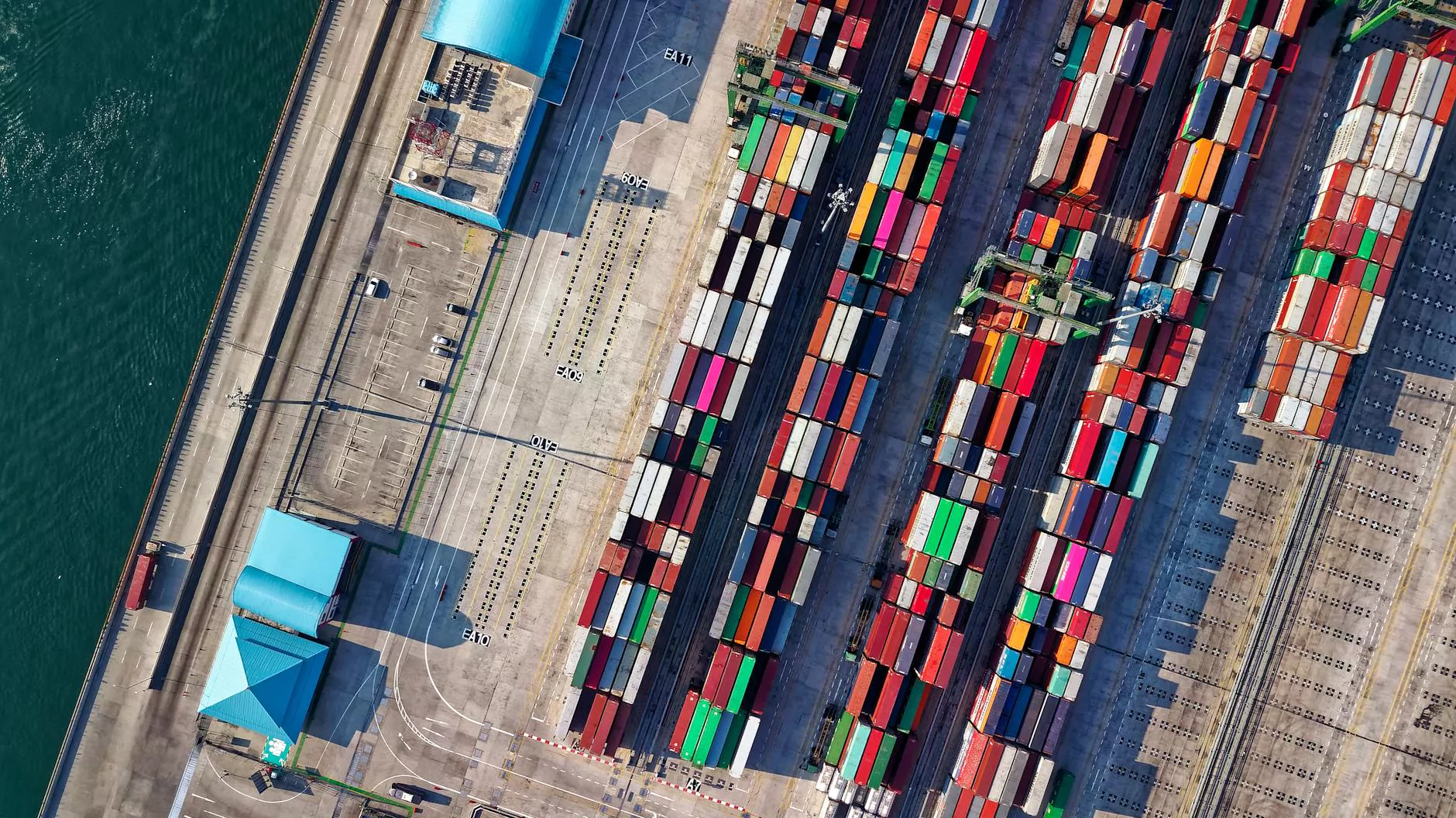

- Production Capacity: China's vast manufacturing infrastructure enables the mass production of components, ensuring quick lead times.

- Technological Advancements: Continuous investment in technology ensures that Chinese manufacturers keep pace with global standards.

- Quality Assurance: Many Chinese manufacturers adhere to international quality control standards, producing reliable and durable products.

Applications of CNC Lathe Parts from China

The china cnc lathe part is employed across various industries, reflecting its versatility and importance. Here are some notable applications:

- Aerospace: Machining precision components that require stringent tolerances for safety and functionality.

- Automotive: Manufacturing parts and assemblies that demand high durability and performance under extreme conditions.

- Electronics: Creating intricate components for devices, including smartphones, tablets, and computers.

- Medical: Producing precision instruments and implants essential for modern healthcare.

Benefits of Utilizing China CNC Lathe Parts

Choosing to use China CNC lathe parts comes with numerous advantages, particularly for metal fabricators:

1. Enhanced Precision and Quality

With advanced manufacturing technologies and rigorous quality control processes, CNC lathe parts from China provide unparalleled precision. This consistency leads to improved product quality and reliability, which is critical in sectors where even the smallest margin of error can have significant consequences.

2. Greater Flexibility in Design

Chinese manufacturers often have the capacity to adapt to specific design requirements, allowing for customized solutions tailored to the unique needs of businesses. This flexibility can significantly enhance efficiency and effectiveness in various production processes.

3. Quick Turnaround Times

The vast production capabilities of Chinese manufacturers mean that lead times for production are generally shorter. Businesses can order parts and receive them quickly, which is essential for meeting tight deadlines and maintaining workflow.

4. Competitive Pricing

Cost is always a consideration in manufacturing. The large-scale production methods used in China enable manufacturers to keep costs low, allowing businesses to maximize their profit margins while still using high-quality components.

Quality Assurance in CNC Lathe Parts Manufacturing

When sourcing China CNC lathe parts, it is essential to understand the quality assurance processes in place. Reliable manufacturers implement various strategies to ensure that their products meet international standards:

- ISO Certification: Look for manufacturers that hold ISO certifications, as they demonstrate adherence to quality management standards.

- Material Sourcing: High-quality raw materials are crucial for producing durable CNC parts. Ensure that manufacturers source their materials from reputable suppliers.

- Laboratory Testing: Many manufacturers conduct rigorous testing on their parts to ensure they meet specific industry standards and specifications.

- Customer Feedback: Reviewing customer testimonials and case studies can provide insights into the reliability of a manufacturer’s products.

Choosing the Right Manufacturer for CNC Lathe Parts in China

Selecting the right manufacturer for china cnc lathe part is a decision that can impact your business significantly. Here are key factors to consider:

1. Experience and Reputation

Research your potential manufacturers. Companies with a long-standing presence in the industry are more likely to deliver quality and reliability.

2. Specialized Capabilities

Different manufacturers have different capabilities. Ensure that the manufacturer has the right equipment and expertise for your specific CNC lathe part needs.

3. Communication and Customer Service

Effective communication is essential for a successful partnership. Choose a manufacturer known for excellent customer service and support throughout the project lifecycle.

4. Pricing and Payment Terms

While competitive pricing is crucial, ensure that the overall costs align with the quality you expect. Transparent payment terms are also essential to avoid any misunderstandings.

Future Trends in CNC Lathe Manufacturing

The future of CNC lathe manufacturing is poised for exciting advancements. Here are some trends worth watching:

- Automation: The integration of AI and robotics in CNC machining is expected to enhance efficiency and reduce human error.

- Additive Manufacturing: The combination of CNC machining with 3D printing techniques is becoming more common, allowing for complex geometries and rapid prototyping.

- Sustainability: There is a growing focus on environmentally friendly manufacturing processes, including the use of sustainable materials and recycling practices.

- Smart Manufacturing: The rise of IoT (Internet of Things) allows for smarter machines that can communicate data in real-time, improving production monitoring and maintenance.

Conclusion

In conclusion, China CNC lathe parts are vital components in the metal fabrication industry, offering precision, efficiency, and cost-effectiveness. By understanding the significance of these parts, their applications, and the importance of quality assurance, businesses can make informed decisions that drive production success.

At DeepMould.net, we are committed to providing top-notch CNC lathe parts tailored to your specifications, enhancing your manufacturing processes and ensuring you stay ahead in the competitive landscape of metal fabrication. Get in touch with us today to discover how our expertise can meet your manufacturing needs!